Major activities of the department

To make sure tissue culture products (plantlets) are designed and developed in a way that takes account of the standard requirements by providing quality assurance check lists.

To make sure the intermediate and finished products are processed and checked according to the specified procedures.

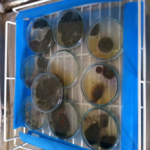

Conducting Environmental monitoring system for all control rooms of the institute and operators of using Settle plate, Swab sample and Finger print Analysis for operators.

Colony counting using stereomicroscope

Petri dish containing fungal colony ( Aspergillus niger)

Physico-chemical test analysis for the RO water in Media preparation, QA, R&D and RO water treatment lines.

Checking the quality of products to be shipped by understanding the quality of manufacturing.

Approval of products and management of the product circulation at an early stage.

Collect the market information and respond to the requirements by linking up with customers and the Sales & Marketing Dept.

Development of the business direction and activation of the interoffice morale by providing initial and contentious training

Micro biology laboratory

Collection of microbial medium

Company-wide quality assurance towards the feedback from customers

Tissue culture protocol development and adaptation of mass propagation of selected and valuable plant species like Sugarcane, Banana, Aloe Vera, Ginger, strawberry, Cassava,

Research and Development unit transfer room

Research and Development unit Growth room

Conducting different research activities and small scale trials to solve problems occur at different stage of production line

Refinement of media formulation protocol in all Stage of plant tissue culture

Discussion concerning the validity of development concept, preproduction units, and mass production sample units

(Figure 1and 2 Good performed In vitro Sugarcane Variety B52/298 which has conducted by R&D Unit on improving standard multiplication media)

Refinement and Optimization protocol on media & fertilizer for platelets in acclimatization (Hardening) stage

(In vitro produced Giant Cavendish Banana plant lets in Acclimatization stage)

Conducting confirmatory test analysis by preparing complete media for new tissue culture chemicals (raw materials) come up to our institute before it’s introduced to the production line

Experiment and review of overall production manufacturing

Training and demonstrations on Tissue culture and other relative techniques for Researchers and higher education students and visitors

Quality assurance, Research and development facilities

• Incubators

• Refrigerators

• Compound and stereoscope Microscope

• RITA Bioreactor

• ELISA reader

• Lux meter

• PH meter

• Conductivity meter

• Sensitive balance

• Water test kit